Sekretariat

INWAT Spółka z o.o.

90-315 Łódź, ul. Jana Kilińskiego 141

Tel. /48 42/ 6363788, 6363245, 6363289

Fax. /48 42/ 6364792

e-mail: info@inwat.com.pl

INWAT Spółka z o.o.

90-315 Łódź, ul. Jana Kilińskiego 141

Tel. /48 42/ 6363788, 6363245, 6363289

Fax. /48 42/ 6364792

e-mail: info@inwat.com.pl

Misją INWATu jest dążenie do pełnego zadowolenia klientów oraz osiąganie w działalności firmy równowagi między środowiskiem, społeczeństwem i gospodarką.

|

Modernization of equipment and installations |

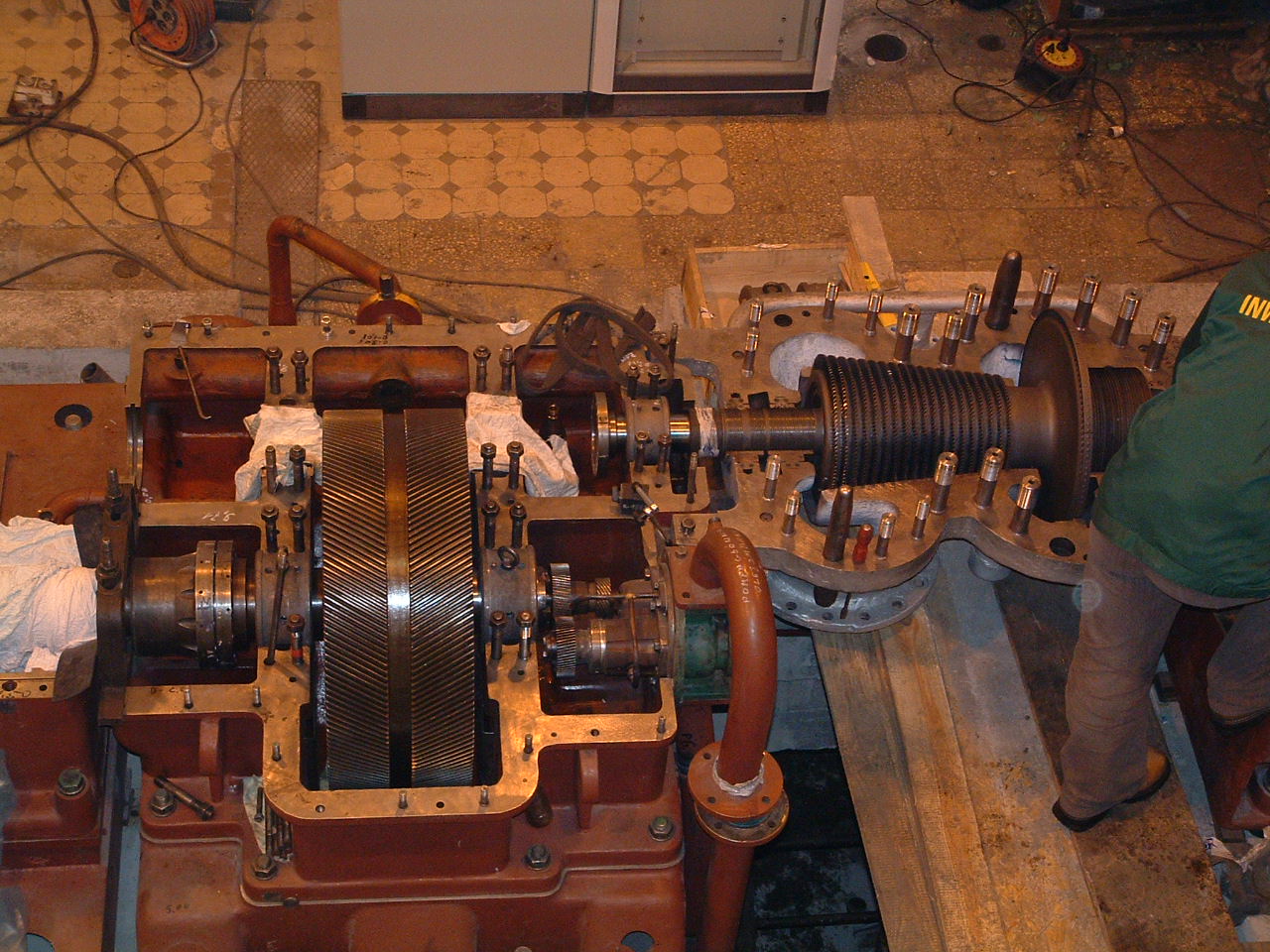

Many years of experience of our engineering staff, specialized in the modernization of steam turbines, enable us to carry out overhaul and modernization works for all types and sizes of steam turbines.

We maintain long-term cooperation with companies manufacturing turbine components and performing turbine overhauls.

Our company is equipped with appropriate facilities for testing, calculations and design, based on a networked computer system. Within the scope of overhauls, we restore the technical condition of turbine units, including the replacement and refurbishment of worn components, ensuring reliable operation of the turbine unit for the required service period. All overhaul works performed by our company are covered by a warranty.

The scope of modernization works includes:

Modernization of the blade system to:

achieve higher efficiency,

achieve increased steam flow rates.

Modernization of the blade system enables an increase in electrical output (within the existing generator capacity limits).

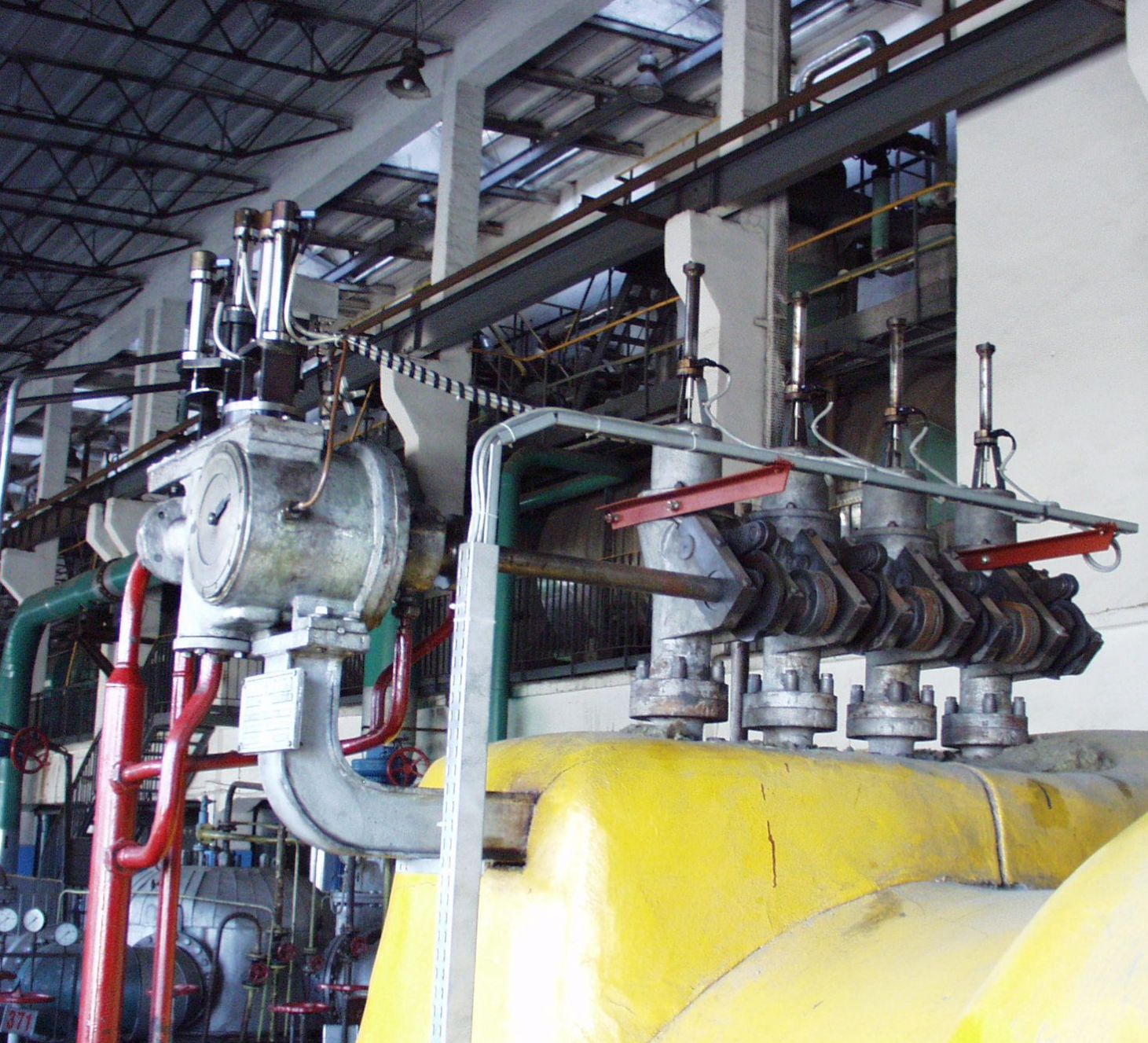

Conversion of condensing turbines into extraction–condensing turbines with controlled steam extraction.

Adaptation of turbines to changed district heating requirements, including:

modification of steam pressure and flow rates at extraction points and at the outlet,

addition of new extraction points,

adaptation of condensing turbines for back-pressure operation,

adaptation of condensing turbines for preliminary district heating water preheating in the condenser under “reduced vacuum” conditions.

Installation of endoscopic inspection ports in turbine casings for inspection of areas prone to potential damage.

Installation of bypass oil filtration systems.

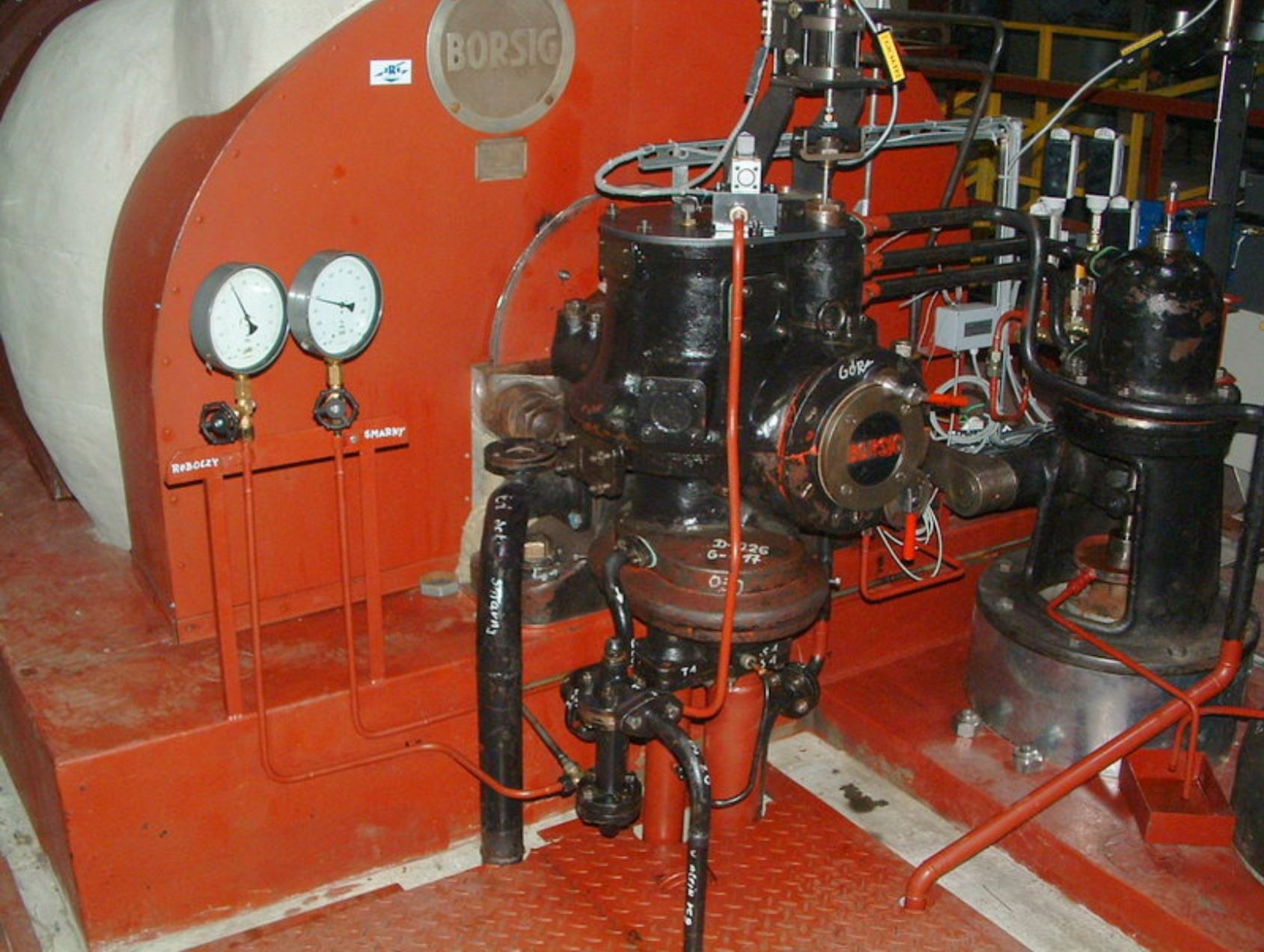

Modernization of control systems and implementation of electro-hydraulic control (EHR).

Installation of vibration and bearing temperature monitoring systems.

Regeneration of large cast components.

Other modernization works, depending on the Client’s requirements.

|

|

|

Mechanical–hydraulic control systems used in older steam turbines are no longer able to meet current requirements regarding reliability and control accuracy. The objective of control system modernization is to reduce the number of mechanical and hydraulic assemblies in the speed and steam pressure control paths (extraction or back-pressure, depending on turbine type) and to replace them with modern electro-hydraulic control systems.

The basic functions performed by the EHR systems designed by us include:

rotational speed control,

automatic speed ramp-up with adjustable speed increase over time and rapid passage through critical speed ranges,

automatic initial loading of the generator,

electrical power control,

control of extraction steam pressure or back-pressure steam pressure, depending on turbine type,

implementation of technological limiters (e.g. steam power limiter, control stage steam pressure limiter, extraction steam pressure limiter, exhaust steam pressure limiter, turbine casing metal temperature limiter, overspeed limiter, thermal limitation block, etc.),

implementation of protection functions (generation of turbine trip signals),

information and monitoring functions (visual and audible signaling of regulator operating modes, normal operating states and turbine fault conditions).

The application of electro-hydraulic governors provides the following technical and economic benefits:

improved control quality through the use of advanced control algorithms,

automation of turbine start-up and shutdown processes,

facilitation of turbine synchronization,

increased turbine operational safety through the use of additional electronic overspeed protection,

reduction of turbine overhaul costs and shortening of control system maintenance downtime,

increased turbine availability through continuous monitoring of technical condition and technological processes,

improved cooperation with heat consumers in the case of district-heating turbines,

enhanced operating comfort for turbine operators.

Our scope of services related to the implementation of electro-hydraulic control includes:

design and engineering works,

supply of equipment,

commissioning, initial operational testing and handover for operation.

|

|

|

|||

|

|

||||

ul. Jana Kilińskiego 141

90-315 Łódź

Tel. (+48 42) 6363788, 6363245, 6363289

Fax. (+48 42) 6364792

E-mail: info@inwat.com.pl

NIP 725-001-27-17

REGON 008068411

KRS 0000119485

Sąd rejonowy dla Łodzi - Śródmieścia w Łodzi,

XX Wydział Krajowego Rejestru Sądowego

Wysokość kapitału zakładowego w całości wpłaconego: 1 000 000,00 PLN

Zadanie p.n. "Termomodernizacja budynku biurowego Zakładu Badawczo-Projektowego "INWAT" Sp. z o.o. przy ul. Kilińskiego 141" dofinansowane przez Wojewódzki Fundusz Ochrony Środowiska i Gospodarki Wodnej w Łodzi.

Podmiot odpowiedzialny za realizację zadania: Zakład Badawczo-Projektowy "INWAT" Sp. z o.o. w Łodzi.

Wartość zadania ogółem 435 918,00 PLN.