Sekretariat

INWAT Spółka z o.o.

90-315 Łódź, ul. Jana Kilińskiego 141

Tel. /48 42/ 6363788, 6363245, 6363289

Fax. /48 42/ 6364792

e-mail: info@inwat.com.pl

INWAT Spółka z o.o.

90-315 Łódź, ul. Jana Kilińskiego 141

Tel. /48 42/ 6363788, 6363245, 6363289

Fax. /48 42/ 6364792

e-mail: info@inwat.com.pl

Misją INWATu jest dążenie do pełnego zadowolenia klientów oraz osiąganie w działalności firmy równowagi między środowiskiem, społeczeństwem i gospodarką.

|

Technical analyses and expert assessments |

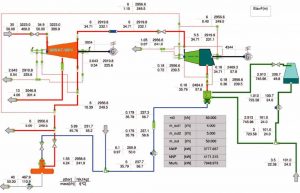

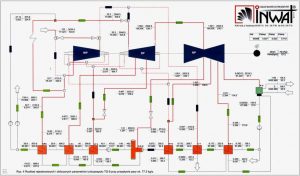

In addition to traditional measurement-based methods for identifying equipment operating conditions, we also possess extensive capabilities for computer modeling of systems, thermal cycles and district heating sections.

For this purpose, we use the best available software solutions and, when necessary, develop our own dedicated applications.

The technical possibilities of modeling are virtually unlimited and include:

power plants with steam and gas turbines,

unit-based systems and header-based systems,

design and off-design operating conditions,

district heating systems,

heating plants, boiler houses, etc.

|

|

We perform expert assessments to evaluate the remaining service life of machines as well as their technical condition after long periods of operation and after failures. We analyze the causes of damage and assess the possibility of restarting turbines with existing defects, such as incomplete blading. We also define the scope of overhaul and refurbishment works.

In the assessment of technical condition and during modernization works, we use software from leading global suppliers, enabling:

strength and dynamic analyses of power engineering equipment components,

modeling of turbine unit operating conditions before and after modernization in order to determine the resulting effects,

modeling of cooperation between multiple turbines and power equipment within a power plant to determine optimal operating conditions,

other analyses related to steam turbines, gas turbines and power engineering equipment, according to Client requirements.

We conduct specialized turbine unit tests, such as measurements of temperature distribution in the flow path and turbine casings, thermal–flow measurements of condensers and district heating heat exchangers, testing of turbine foundation deformations (including shaft line alignment correction), and endoscopic inspections.

We also perform mechanical service inspections of gas turbines, including borescope inspections.

Ensuring long-term, safe operation of steam pipelines requires systematic monitoring of their technical condition. Such monitoring allows assessment of the degree of component wear and development of appropriate recommendations for repair or replacement of elements at risk of damage, and—where necessary—implementation of modernization measures.

Typical diagnostic testing usually includes:

visual inspection of suspension systems and pipeline surfaces (including endoscopic inspections),

magnetic testing of welds and external surfaces of pipe bends,

examination of material structure on external surfaces of bends or fittings using the replica method,

hardness testing of material at selected locations,

measurements of diameter deformation and ovalization of bends,

wall thickness measurements and internal surface crack assessment (ultrasonic testing),

strain-gauge stress measurements.

The above set of tests generally allows reliable assessment of the technical condition of pipeline materials and enables planning of ongoing repairs and component replacements, provided that such inspections are carried out systematically.

|

Turbine casing stress calculation |

Distribution of reduced (von Mises) stresses from axial and circumferential forces in the blade profile |

Velocity vectors – lower flap of the LP turbine |

geodetic surveys of pipeline position and displacement,

testing of forces and stresses occurring in individual components.

We offer the full scope of the above tests, tailored to the Client’s requirements.

We also provide preparation of as-built (reverse-engineering) pipeline documentation for the purposes of IDT.

|

|

|

|

ul. Jana Kilińskiego 141

90-315 Łódź

Tel. (+48 42) 6363788, 6363245, 6363289

Fax. (+48 42) 6364792

E-mail: info@inwat.com.pl

NIP 725-001-27-17

REGON 008068411

KRS 0000119485

Sąd rejonowy dla Łodzi - Śródmieścia w Łodzi,

XX Wydział Krajowego Rejestru Sądowego

Wysokość kapitału zakładowego w całości wpłaconego: 1 000 000,00 PLN

Zadanie p.n. "Termomodernizacja budynku biurowego Zakładu Badawczo-Projektowego "INWAT" Sp. z o.o. przy ul. Kilińskiego 141" dofinansowane przez Wojewódzki Fundusz Ochrony Środowiska i Gospodarki Wodnej w Łodzi.

Podmiot odpowiedzialny za realizację zadania: Zakład Badawczo-Projektowy "INWAT" Sp. z o.o. w Łodzi.

Wartość zadania ogółem 435 918,00 PLN.